Fused cast block

Other name:Fused cast AZS refractory block

Model Number:Fused cast block, fused cast AZS 33/36/41 bblock

Certification:ISO 9001-14001

Minimum Order Quantity:5MT

Fused cast blocks introduction

Fused cast block, sintered brick and non-fire brick are three kinds of refractory block. Fused cast block is made by the way of electric smelting tech. With the different ingredients of raw material, fused cast block can be divided further as fused mullite block, fused AZS block, fused zirconia-alumina block etc. Fused refractory materials is widely used in the field of steel & iron manufacture, nonferrous metals smelt, building material industry and other industrial furnace .

As the name implies, fused cast block is created by pouring mixed liquid into block mold. Putting certain proportion of raw material with binding material into electric arc furnace and melted them under high temperature about 2500 ℃, then we will get the mixed liquid used for pouring. The most common is fused cast AZS block. According to the zirconium’s percentage in block, fused cast block can be classfied into three kinds which are fused cast AZS 33 block, Fused cast 36 block and fused cast AZS 41 block. Different kinds refractory block with different zircon content has different index of chemical and physical, also with different usage.

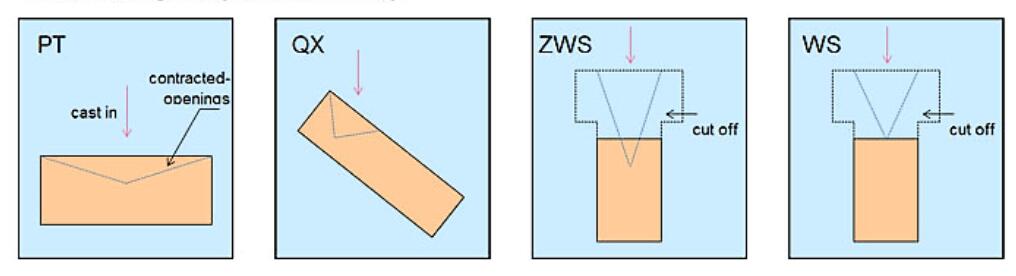

Fused cast block casting methord

There have four methods to make fused cast block:PT/QX/ZWS/WS .The different distribution area, quality of shrinkage cavities and dense part are the ways to know which fused cast method the block used.

PT-Normal casting, shrinkage cavities are located on the upper part of block, just under the in-pouring hole.

QX-Tit casting,the fused cast mold is tilting,so the shrinkage cavities spread over the ridge close to in-pouring hole. And the rest part is definitely dense.

ZWS- End casting,The casting track almost like WS is the cast method without shrinkage cavities (ZWS). By using this method, there is a little cavities on the block.

WS-Void free casting, this method is vertical casting with special shrink head, and the shrinkage cavities focus around the shrink head. After annealing, the shrinkage cavities part will be cut off based on the certain sizes. So the block we finally get has no shrinkage cavities.

Fused cast block application

Huachen refractory will chose the proper cast way base on the characters of the four cast methods and customer’s request. No matter which cast method we chose, during the post processing, we used the most advanced equipment like cutting, drilling to ensure the accuracy and precision of processing quality and improve the fused cast block’s quality, and in the end prolong furnace’s service life.

Fused cast block with PT cast method usually be used on the upper part of glass furnace, working end of the tank or the low temperature part which exposed to glass metal. And the block produced using the QX, ZWS method mainly be used for glass furnace working end and the sidewall of working end. block used WS cast method can be used at the key part of glass melting furnace throat, feeder channel , dog hole, the bottom of working tank and so on.

Fused cast blcok technical process

The technical process flow of making fused cast block:

Material--Batch mixing--Melting--Casting--Insulation-- Taking out after annealing--Sample inspection--Finishing--Final inspection--Assembling, inspection--Package and shipment