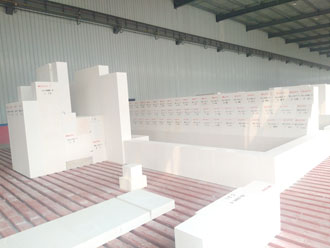

Fused cast AZS 41 block

Other name:Fused cast AZS 41 refractory block,Fused cast block ER 1711,Fused cast block ZB 1711,Fused cast block CS-5,Fused cast block UNICOR 1, Fused cast block REFEL1240

Model Number:Fused cast AZS 41 block

Certification:ISO 9001- 14001

Minimum Order Quantity:5 MT

Fused cast AZS 41 block introduce:

Using WS cast method, fused cast AZS 41 refractory block is high quality refractory with zircon sand and industrial alumina powder as its raw material, and the percentage of ZrO2 is 41%. Among zirconia-alumina brick (AZS) series, fused cast AZS 41 refractory block has the best corrosion resistance from glass liquid, and the glass pollution nearly close to null. So fused cast AZS 41 block usually be used in key part of glass furnace that demand high corrosion resistance like electric-melting tank, dog hole, doghouse corner, tank bottom bubbling brick and so on.

Fused cast AZS 41 block Physical and Chemical:

Chemical Composition ( % ) | AZS 41 | |

ZrO2 | ≥ 40.5 | |

SiO2 | ≤ 12.5 | |

Al2O3 | Remains | |

Na2O | ≤ 1.2 | |

Fe2O3 + TiO2 | ≤ 0.25 | |

Physical characters | ||

Volume density (hardest part) | ≥ 4.05 | |

Cold crushing strength (Mpa) | ≥ 300 | |

Exudation Temp. of glass phase (℃) | ≥ 1420 | |

Refractorinessunder load of beginning (0.2MPa) | 1700 | |

Corrosion Resistance to glass melt 1300℃ x 10h ( mm/24hr ) | 0.7 | |

Bulk density (g/cm3 ) | PT | ≥ 3.55 |

QX | ≥ 3.55 | |

ZWS | ≥3.85 | |

WS | ≥ 3.95 | |

Crystalline phase composition ( % ) | ||

Baddeleyite monocrystal | 40 | |

Fused cast AZS 41 block dimension (unit:mm)

Thickness | Width | Length |

Cast method | ||

Standard | Recomm-ended | Standard | Recomm-ended | Recomm-ended | |

250 | 200-400 | 400 | 200-450 | 600-1500 | WS |

300 | |||||

350 | |||||